Horizontal Directional Drilling

We provide mission critical services for the midstream pipeline construction and utility industries.

Ideal Use Cases for Horizontal Directional Drilling

Under wetlands, streams, rivers, and archaeological sites

When trenching is not an option (highways, congested areas, utility conflicts)

To solve landowner disputes for use of ground surface (e.g., agriculture)

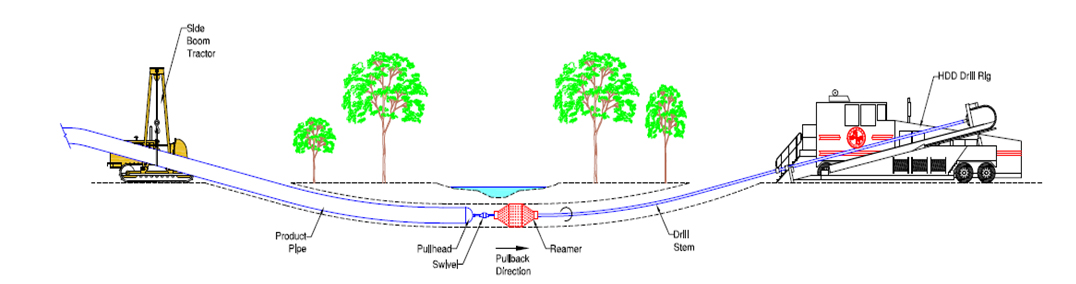

The Basics of HDD

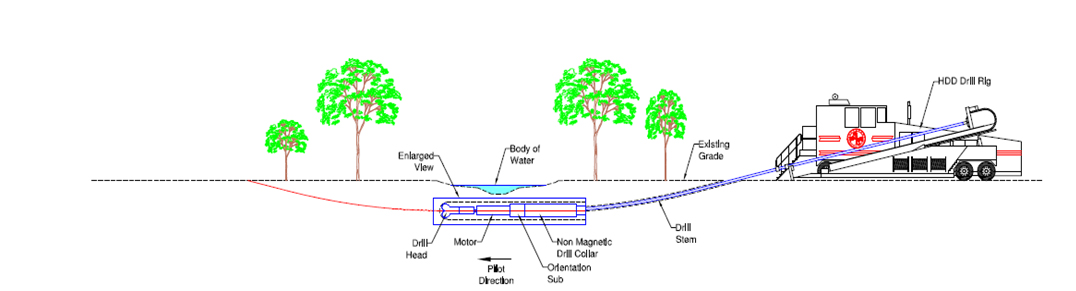

1. Pilot Hole Process

- Pilot hole drilled along a predetermined path, guided by magnetic or gyroscopic steering tools

- Drilling fluid lubricates drill stem and carries debris to surface

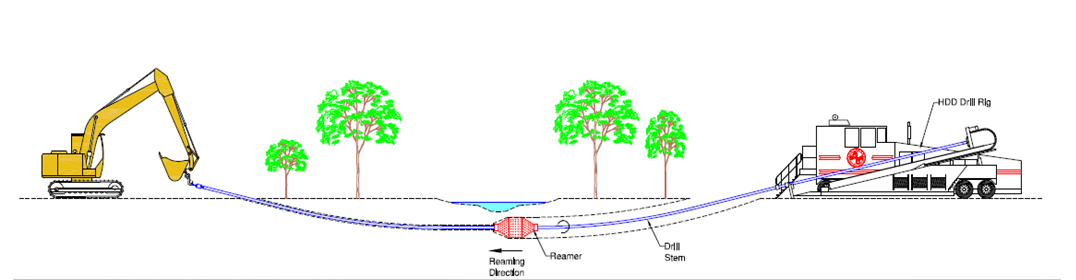

2. Reaming Process

- Larger reamer used to drill hole to specified diameter

- Drill mud pumped through hole to clear debris from path

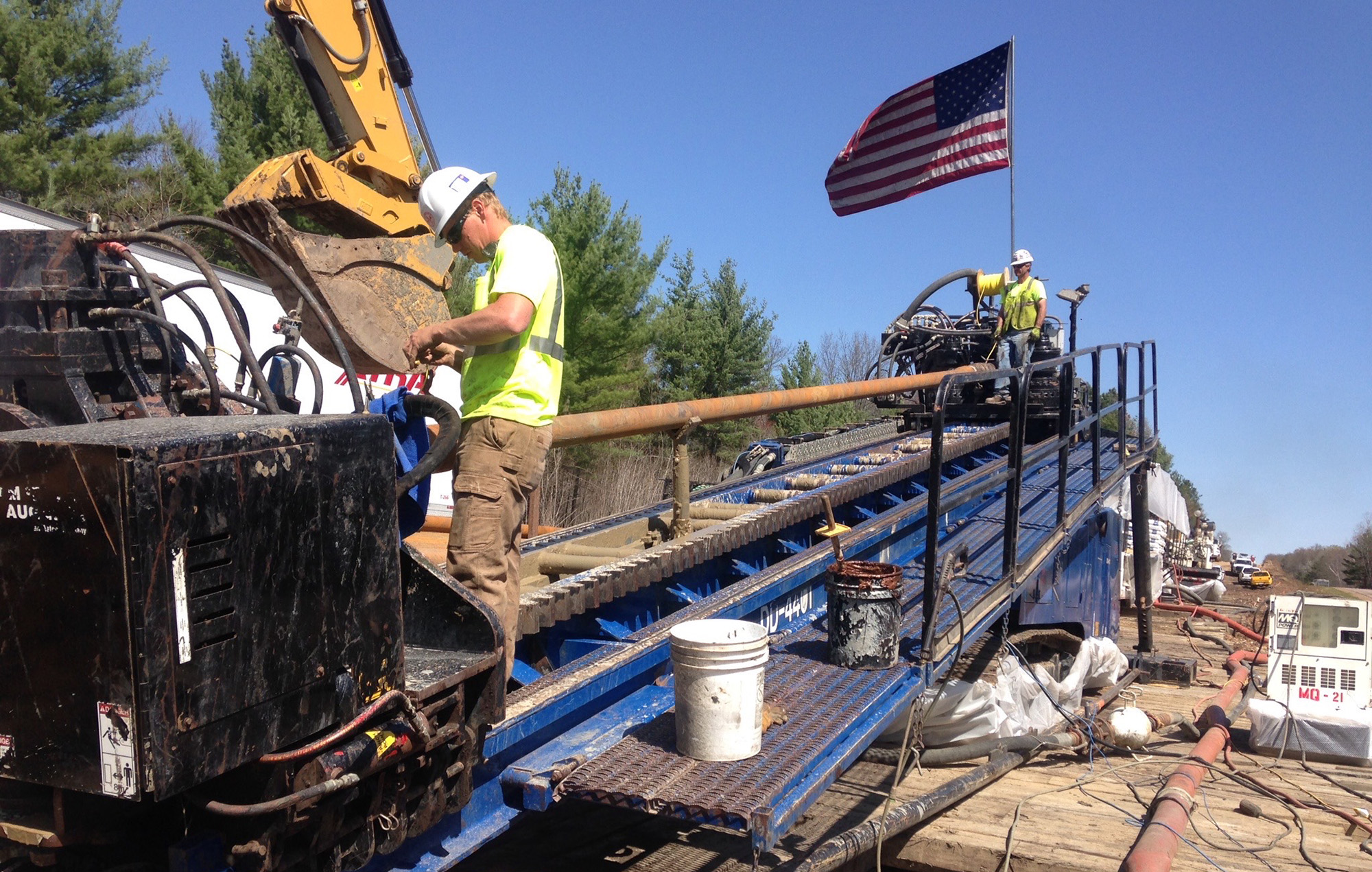

Why Choose North Country?

Horizontal Directional Drilling is 100% of service. You won’t find another company as commiutted to this technology and service as NCDD.

- Reputation for high quality execution

- Equipment to handle all sizes and lengths of projects

- Expertise in high value, large diameter drilling

- Safety driven from job planning through job execution

- Superior technical excellence – highly experienced personnel

- Knowledge in drilling through all types of soil conditions, including hard rock, cobbles, and clays

- Proprietary equipment with a full‐time mechanic organizing the proper maintenance balance

- Unsurpassed success rate – every drill under contract completed